Right now at Alde

See all newsComfortable, silent heating all year round in all weathers

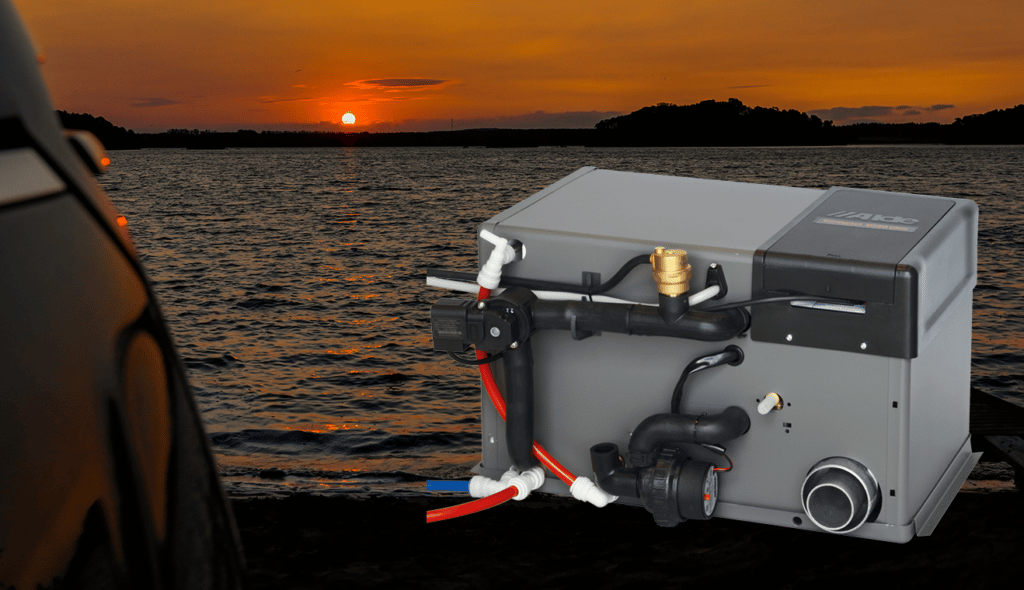

If you want to fully enjoy lifes journey to the maximum, Alde Heating is your best choice. The heat circulates silently and envelopes you in a comfortable climate with natural humidity.

We are Alde

Alde International Systems AB is a world-leading company which develops, produces and markets heating systems for caravans and motorhomes. You can find us at some of the world’s leading trade fairs – or maybe when you’re staying in one of the fabulous recreational vehicles available on the market.